InvisiGlass: reliable protection, now made with recycled glass.

September 9, 2024

Up to 62% more durable than tempered glass.*

Discover unmatched strength and durability that’s better for Mother Earth. The newest addition to the ScreenForce family, InvisiGlass is our first-ever, glass screen protector made from recycled glass.

Shop InvisiGlass screen protectors here.

We care deeply for the future of our planet.

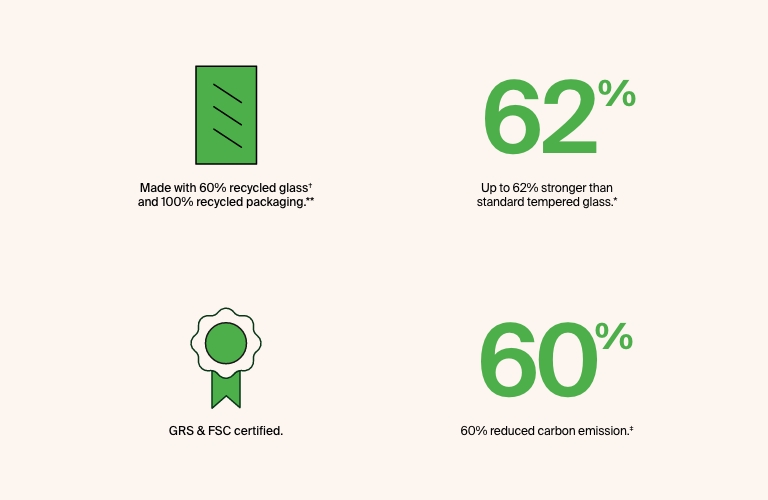

Sustainability isn’t just a trend – it’s our responsibility. Not only is it the right thing to do, but we want to go about it as transparently as possible. According to the EPA, less than one third of glass is recycled in the U.S., and we’re here to change that. In 2024, we’re making huge strides with the introduction of InvisiGlass, made using 60% recycled materials and 100% recycled packaging.

Learn more about Belkin’s sustainability efforts here.

InvisiGlass is an example of how we’re taking action.

Made with 60% PIR (post-industrial recycled) glass.

InvisiGlass is made with PIR glass created during the manufacturing process. Reducing and reusing this waste decreases our need to constantly source virgin raw materials that contribute to environmental harm.

Smaller carbon footprint.

With InvisiGlass, we average a 60% carbon emission reduction when compared to our non-recycled screen protectors.‡ This improvement keeps us on track to achieve our carbon neutral goals.

GRS and FSC certified.

GRS certification (Global Recycled Standard) ensures that our product is made with recycled content, avoids unethical sourcing, and treats workers fairly. We’ve also transitioned to Forest Stewardship Council (FSC) certified paper in our packaging, responsibly sourcing materials, safeguarding forests and respecting indigenous peoples' rights. The goal of these certifications is to continue innovating using reclaimed materials, establish supply chain transparency and to provide consumers with accurate information.

Uncompromised strength.

Sustainability and strength aren’t mutually exclusive. InvisiGlass is fortified with ion-exchange technology, making it up to 62% more durable than tempered glass screen protectors without adding thickness or weight.

What are the benefits of PIR?

Where does InvisiGlass’s PIR glass come from?

Our PIR glass comes from screen protection and cover glass production lines. By consciously reusing material waste including scrap and trimmings, we’re able to remove this waste from the waste stream, recycle it and transform it into materials we can use to manufacture new products.

Why are we using PIR glass?

We’re constantly improving how we use recycled materials across various product lines. PIR allows us to repurpose high-quality glass that meets our performance expectations and standards of durability. This approach not only reduces environmental impact by minimizing waste, but also ensures our products are reliable and long-lasting.

What’s the difference between PIR and PCR glass for screen protection?

Post Consumer Recycled (PCR) materials are extremely valuable and widely used to make many of our products. This keeps materials out of landfills after the product’s end of life. Post industrial Recycled (PIR) also keeps materials out of landfills and supports circularity within our supply chain. Our glass is scientifically engineered for strength, absorbing fall impact and preventing scratches. This requires glass with high optical quality. Using post-industrial recycled glass allows us to ensure purity and eliminate contaminants while still supporting recycling efforts throughout our supply chain.

InvisiGlass at a glance

1%

Up to 62% stronger than tempered glass*

1H

Highest scratch resistance on Pencil Hardness scale.

1%

Made with 60% recycled glass†

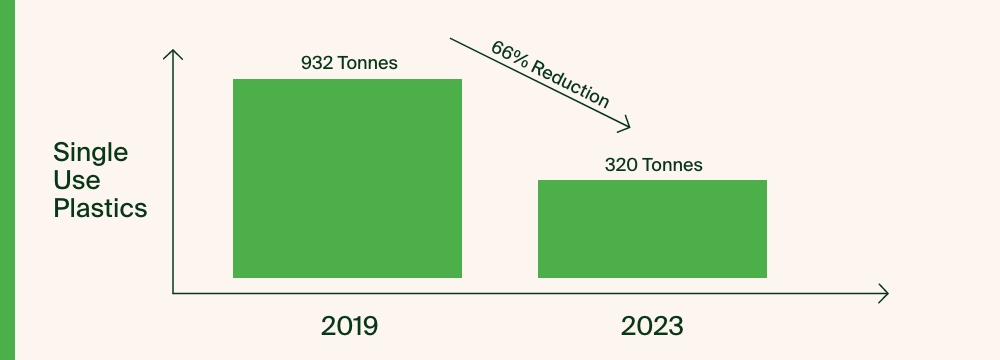

Addressing single use plastic packaging.

100% recycled plastic packaging**

InvisiGlass recycled packaging components include the Easy Align tray, support tray, top protective film, and protective bags. Since transitioning to post-consumer recycled (PCR) materials for packaging in 2022, we’ve sold 4.4 million products, replacing 64 metric tons of single-use plastic. That’s about the same as 42 cars or 10 elephants.

Here’s a breakdown of InvisiGlass packaging components and how to make the most out of each item.

*Based on internal tests, screen protectors can withstand up to 62% more force on average compared to conventional tempered glass screen protectors.

†Glass is made of a minimum of 60% post-industrial recycled glass and has been certified through GRS.

‡Based on internal calculations with an average screen protector weight of 7.4g.

**Recycled plastic components include Easy Align tray, support tray, top protective film, and protective bags.

ABL+AM-ScreenProtector-WebG-US-01.jpg?sw=280&sh=280&sm=fit&sfrm=png)

+AM-ScreenProtector-WebG-US-01.jpg?sw=280&sh=280&sm=fit&sfrm=png)

+AM-ScreenProtector-WebG-US-01.jpg?sw=280&sh=280&sm=fit&sfrm=png)