Destination: a more responsible future.

We care deeply for the future of our planet. While we take pride in our achievements as a leader in corporate sustainability, we’re always looking ahead, setting new goals, and reaching for higher standards. Stay in step with our sustainability journey and join us as we lead the way to a more responsible future.

How do we reduce our environmental impact?

Since transitioning to post-consumer recycled (PRC) materials, we’ve sold 8.8 million PCR products, replacing 432 metric tons of virgin plastic. That’s about the same as 288 cars or 86 elephants. Plus, we sell 50M+ products annually in 100% single-use, plastic-free packaging. Our overall plastic use, including recycled plastic, has decreased by 89%. Single-use plastic was reduced from 932 metric tons in 2019 to 403 metric tons in 2024.

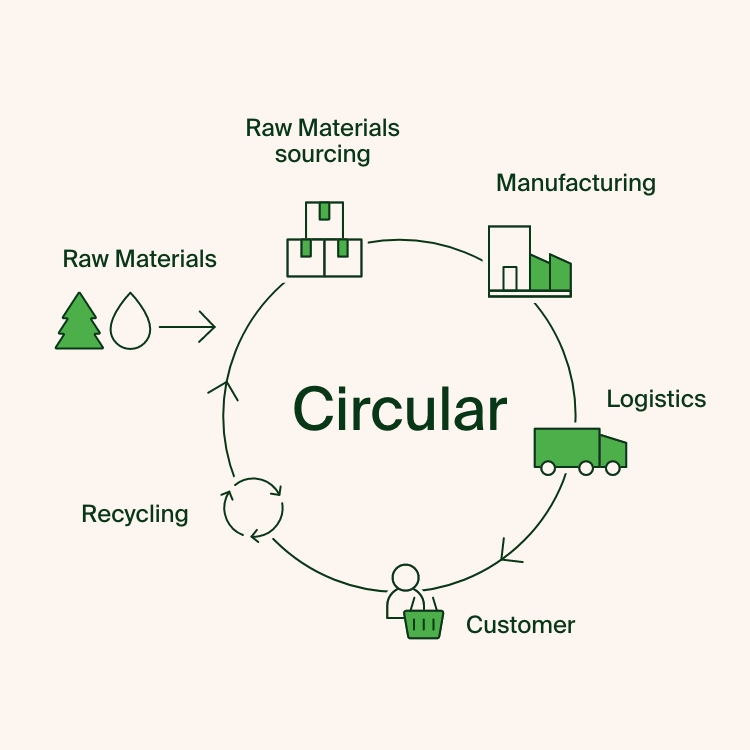

What happens with our product life cycle?

Globally, we actively participate in various e-waste recycling programs. Since 2009, we funded the recycling of 27,405 metric tons of electronic waste, 764 metric tons of batteries and 10,734 metric tons of packaging — and packaging is equivalent to the weight of over 7,000 average-sized cars. Belkin employees diverted over 77,614 lbs. of e-waste away from landfills with support from e-waste partner HUMAN-I-T ensuring metals and chemicals don’t contaminate soil, groundwater and air.

How do we keep our supply chain ethical and transparent?

Over 149 supplier audits are conducted annually to ensure compliance with labor and environmental regulations and adhere to industry standards such as the Responsible Business Alliance (RBA) Code of Conduct. We publish annual impact reports to provide visibility into the supply chain and demonstrate our accountability to our customers.

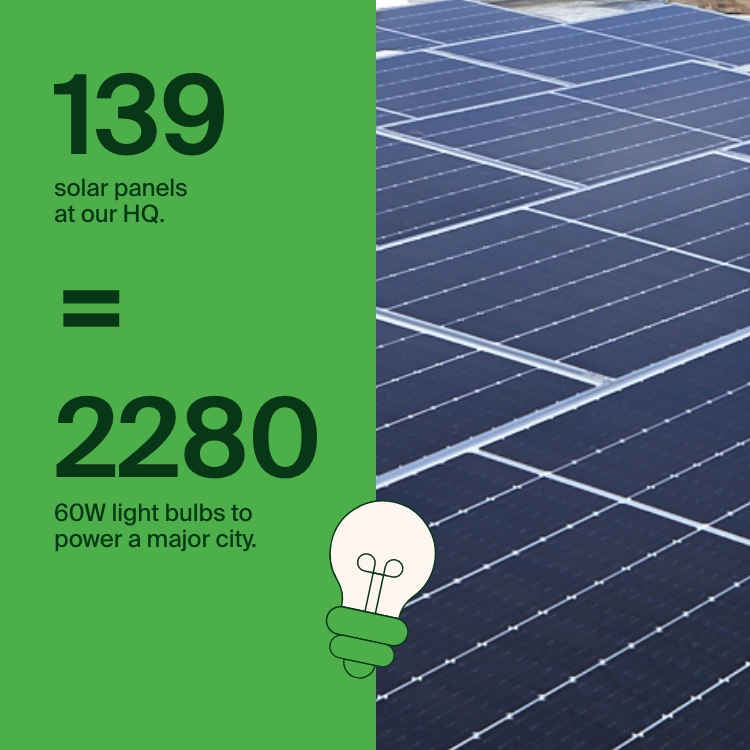

How do we utilize renewable energy?

Renewable energy will match 100% of our global electricity usage. We were at 25% in 2020, 35% in 2021, and 63% in 2023. We installed 285 solar panels at our global headquarters in California to generate clean energy for our office. This 136.8 kW system brings energy equivalent to powering about 100 standard homes. In our Indiana distribution center, we’re purchasing renewable energy credits from the local Agriwind wind farm and supporting renewable energy development.