What is PCR plastic, and why should you care?

April 18, 2024

Sustainability isn’t just a trend – it’s our responsibility. Not only is it the right thing to do, but we want to go about it as transparently as possible.

Throughout 2024, we’re transitioning the housing of all our new products (and some of our best-selling products) to use 73-75% recycled materials. This will reduce plastic product housing CO₂ emissions by up to 67%. By transitioning our products from last year to incorporating 73-75% PCR materials, we saved an estimated 636 metric tons of CO₂ emissions. Great news, right? But with the term “recycled plastics” becoming more and more common, we thought we’d use this post to focus on the ins and outs of recycled plastics, and what this term really means. What are they, why do we use them, and how are they better for Belkin than the alternatives? Read on for the answers to all your questions!

PCR plastics and the circular economy.

At Belkin, sustainability is fundamental to our organisation, which is why we’re continually improving the products you love (and new products you’ll love in the future) by integrating PCR plastics and other low-impact materials into them. But what do we mean by ‘PCR’, and why is it an important part of the bigger picture?

In the context of plastics, ‘PCR’ stands for ‘post-consumer recycled’. This means that when you’re ready to dispose of a product, instead of going to landfill, the plastic in the product is recycled into pellets. This allows it to be used again to make another product. In other words, PCR is plastic that’s made from plastic that already exists – although to make sure the plastic is still great quality after processing, the recycled pellets are often mixed with new (‘virgin’) plastic.

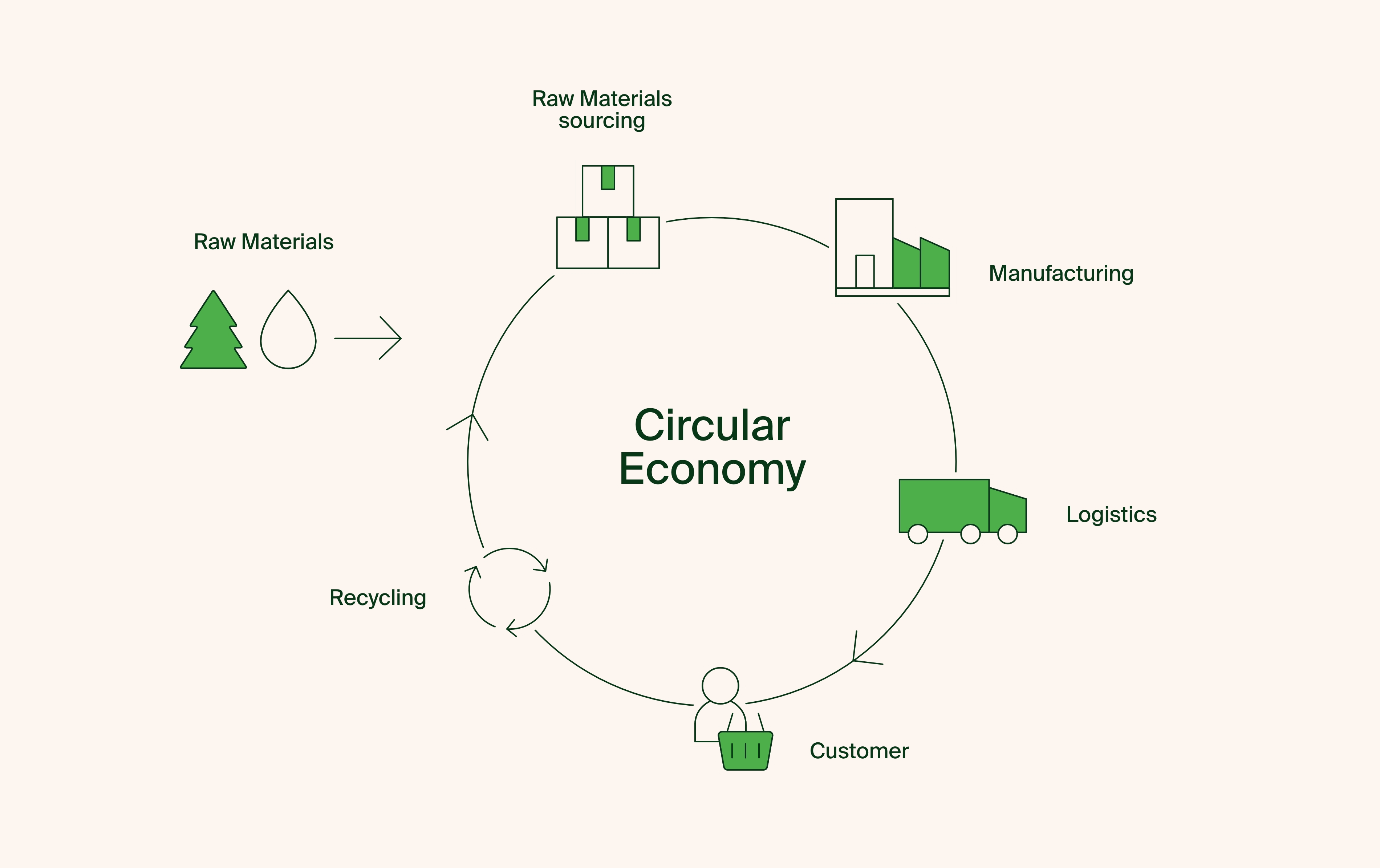

There’s another important concept at play here, and that’s what’s known as the circular economy. This is the idea of keeping materials in use for as long as possible. This decreases our need to constantly source virgin raw materials, while also designing waste out of the system. This ‘closes the loop’, diverting materials from landfill, giving them a new life so they can be used again. There’s a great animation from the Ellen MacArthur Foundation that explains this in more detail.

The circular economy mirrors the natural world, where materials are building blocks that form part of a continual cycle in which living things grow, die and return to the earth to grow again into something new. Taking this idea and applying it to manufacturing, we can see that recycling is a key part of the circular economy.

To reduce our dependency on the world’s natural resources for products that get disposed of in a few years, we need to recycle them into new products. Along the way, that means finding ways to process materials so that they can be used for other things, while maintaining their original quality. Quality is important – a charger that easily breaks after regular use could end up as e-waste quite quickly. Products that are built to last can continue to be used for much longer.

The circular economy lies behind our decision to transition all our applicable products to PCR plastic, both new and existing, instead of simply making a new line of products from this material and continuing to use virgin plastic as usual. In doing so, we can better contribute to the circular economy and make a much bigger impact on reducing waste and emissions.

What are the other types of recycled material?

PCR plastic isn’t the only type of recycled material out there, so what about the others? Here’s a look at some of the top contenders.

Post Industrial Recycled (PIR): This is plastic waste generated during the manufacturing process. Reducing and reusing this waste is good manufacturing practice, but it only removes waste from the manufacturing process and not from where the end user recycles e-waste. You might notice companies making claims about their products being made of recycled material, but it’s often not specified where the material came from – is it PCR or PIR plastic?

Ocean plastic: Exactly as it sounds, ocean plastic is post-consumer plastic that’s been removed from the sea. This plastic is often harder to process because of the time it’s been exposed to UV from the sun and salt from the water.

Ocean-bound or marine plastic: This is plastic that’s at risk of ending up in the ocean. It’s typically collected within 50km of a shoreline in areas in which waste management isn’t deemed good enough to prevent it from entering the ocean, and where the waste in question isn’t already in landfill or another waste management facility.

Bio plastic: Bio plastic is created from renewable biomass sources. That could be anything from corn to sugarcane to sawdust to mushrooms. It’s a great alternative plastic for products that require flexibility – such as straws or cables. This material has the potential to contaminate plastic recycling streams, so it’s important to use caution when implementing this material.

With so many different types of recycled plastic to choose from, this raises a question…

Why does Belkin use PCR over other recycled materials?

We challenged ourselves to use an alternative plastic housing with the same look, feel and performance as our original products, while also reducing material consumption. But why have we chosen PCR over the other types of recycled plastic available?

First and foremost, transitioning to PCR plastic is the right thing to do. It also supports the circular economy by minimising the use of raw materials and repurposes waste that would otherwise go to landfill. It’s a better choice for the circular economy than PIR plastics, because PCR uses materials that you, the consumer, recycle, rather than simply recycling at the factory.

What’s more, the source of PCR plastic can be certified, so we know it’s authentic – meaning we know where it came from and what went in to making it. Its structural integrity is equivalent to virgin plastic, meaning there’s no comprise to the quality and performance you know and love from Belkin.

We’ve chosen to use up to 75% (and not 100%) PCR plastic in our products because we didn’t want to compromise our quality requirements. We’re always looking to find the highest % of PCR plastic for our products and are on the way to incorporating a higher %. This way, we can ensure we’re still making a product that lasts to keep our products in use for as long as possible.

What about the packaging?

Of course, the products themselves are only part of the picture – the packaging they come in makes a big difference too. We’ve been actively reducing the level of plastic in our packaging for some time, eliminating it by 100% single use plastic in our latest products.

Our packaging uses Forest Stewardship Council (FSC) certified paper. This certification ensures the paper is sourced from forests that promote environmentally responsible, socially beneficial, and economically viable management of the world’s forests. This commitment not only enhances the circular nature of our packaging, but also plays a vital role in protecting the long-term health of the world’s forests.

How to recycle a Belkin product?

The good news is that it’s easier than ever to recycle your old Belkin products. They can contain valuable, salvageable materials, including aluminium, copper and precious metals, all of which can be used again in other products.

Our E-waste Recycling Program is a free recycling program available throughout the United States, and it ensures that your Belkin products can be recycled in such a way that nothing goes to landfill. You can get started here. In other regions, we pay to support recycling programs in which the local municipality recycles e-waste on our behalf.

When it comes to recycling the packaging that your Belkin products come in, we’ve noted that we’re on a journey to plastic-free packaging and are now using paper certified by the FSC. Paper is one of the most recycled materials worldwide, so this means you’ll be able to put our packaging in with your normal household recycling.

PCR plastics FAQ:

Let’s end this look at PCR plastics by answering some of our most frequently asked questions on this fascinating subject.

There’s no easy answer to this, because some is, and some isn’t. By sending your Belkin products back to us at the end of their useful life, we can ensure they’re recycled whenever possible.

PCR plastic is a more responsible material than virgin plastic, but it’s still a petroleum-based plastic. That means it isn’t biodegradable, so it wouldn’t break down if you were to put it on a compost heap and living microorganisms can’t eat it.

‘Post-Consumer Recycled’ refers specifically to materials that have been recycled after they’ve been sold to consumers like you – so for example, it could be plastic that’s made from cleaned and reprocessed bottles that you discarded with your household recycling.

The more general word ‘recycled’, on the other hand, is a catch-all term for any material that’s been recycled at any stage during its lifetime. It could therefore refer to Post-Consumer Recycled plastic or Post-Industrial Recycled plastic reprocessed from waste during the manufacturing process (such as excess plastic used in making plastic water bottles).

It’s not always obvious from looking at a product or its packaging whether it’s made with virgin or PCR plastic. You’re getting the benefits of plastic, such as its strength, durability and versatility. It may say so on the product’s packaging, but if you’re ever in doubt, we’ll let you know when we’ve used PCR plastics in your Belkin products.

Want to learn more about what we’re doing to minimize our environmental impact? Read more about Belkin’s sustainability commitments and shop our products available in PCR now.

*73-75% of product's plastic parts made of PCR.

Shop our PCR products.

We hope you enjoyed this post. Signup for blog alerts, product announcements, and exclusive deals via emails and texts now.